How Does Hydrogen Generation Work?

Introduction

The emission of greenhouse gases (GHG) increased through the 20th century, and it continues until today due to the use of fossil fuels to fulfil our energy requirements [1]. However, there is strong drive from governments and society to decrease their use and minimise the amount of GHG emissions, mainly carbon dioxide (CO2), which seems to be, together with methane, the possible cause of global warming resulting in heatwaves, frequent wildfires, floods, droughts, rising sea levels and acidification of the seawater resulting in coral reef degradation. Although it is possible that the increasing concentrations of CO2 affects the atmosphere balance, it is also important to recognise that CO2 is essential for life and helps to maintain a stable temperature in the planet by forming a protective layer that stops heat from escaping the earth [2].

The concentration of CO2 is currently around 420 parts per million (ppm) in the atmosphere and roughly increases 2.4 ppm per year [3]. The earth naturally generates around 770 Gigatons of CO2 per year due to volcanic activity, organic material decomposition and other natural processes but has the capacity to adsorb it through the earth carbon cycle that includes photosynthesis in plants and phytoplankton in the ocean, and other mechanisms [4]. Our human activities contribute with additional 40 Gigatons per year that represents 4-5% of the total. The earth adsorbs half of this human generated CO2 naturally too. However, we still contribute with 20 Gigatons extra of CO2 that the earth is unable to adsorb.

The use hydrogen (H2) instead of fossil fuels, as energy carrier, can help to decarbonise the energy and transport sectors and help to decrease GHG emissions as its combustion only generates water and heat instead of GHG. The challenge is to generate hydrogen without the aid of fossil fuels combustion. Hydrogen is the simplest and most abundant element in the earth and although there are recent reports of natural occurring hydrogen [5], in most cases hydrogen is part of a chemical compound like water and hydrocarbons that must be release through a chemical reaction. Nearly 95% of the hydrogen been generated comes from the steam reforming (SR) process of natural gas and coal while the other 5% is mainly from electrolysis of water. There are other production methods and currently there is a sort of “hydrogen rush” supported by government policies and grants, industry, and the public, to find or to optimise hydrogen production with minimal or cero CO2 generation or at least by capturing the CO2 generated during H2 production. Although hydrogen is a colourless gas, its production methods receive different colour codes, for example, natural occurring hydrogen is white hydrogen whereas hydrogen from carbon and fossil fuels is black and brown hydrogen, respectively [6]. Figure 1 shows some of the most common methods of hydrogen production in an schematic view whereas Table 1 lists some advantages and disadvantages together with other less common methods of hydrogen production not illustrated in Figure 1.

Hydrogen from fossil fuels

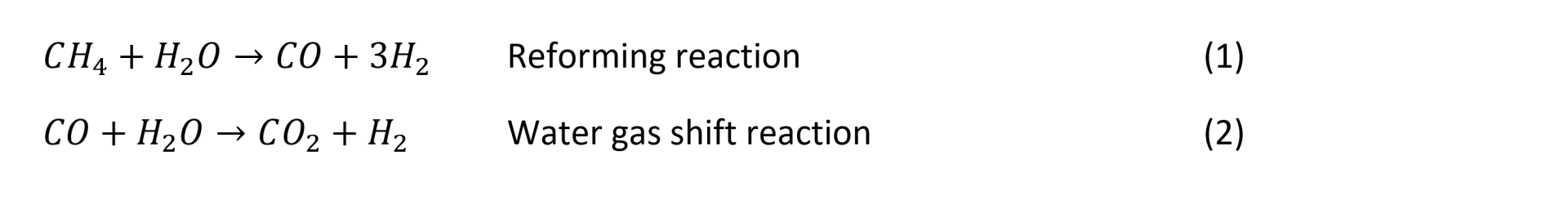

The cheapest and most common method to produce hydrogen at large scale is the Steam Reforming (SR) process that generates 95% of the worldwide hydrogen available. This requires high-energy (endothermic) input in processes carried out between 700 - 1000 oC temperature range and 3 – 25 bar pressure with a platinum, rhodium or nickel, catalyst. The typical efficiency is 70–85 % and the reactions for methane for example, are:

Although this is a very reliable process, it is complex and should be replaced with a method that generates blue hydrogen that captures and stores the carbon dioxide generated.

As well as the steam reforming method, other hydrogen production methods using fossil fuels include:

1. Partial oxidation (POX). - this method consists of gasifying the raw materials, typically heavy oil fractions that are challenging to process, in presence of oxygen at 1300 - 1500 OC and 3 - 8 MPa pressure. The conversion efficiency is lower than SR and generates more carbon monoxide (CO). The advantage is that releases energy (exothermic) unlike SR [7].

2. Autothermal reforming (ATR). - combines SR and POX to reform complex hydrocarbons such as kerosene and diesel [8].

3. Dry reforming (DR). - use natural gas and carbon dioxide to produce hydrogen although ethanol can be used instead of natural gas too [9].

Using fossil fuels as energy source and hydrogen generation inevitably produces CO2, and the resulting hydrogen might contain traces of other unreacted constituents such as carbon monoxide or hydrocarbons traces. Since the fossil fuel composition varies depending on the location, purification of the hydrocarbon gas used is required to remove sulphur compounds, as in the case of the methanol or methane steam reforming (MSR) process. Removing these contaminants is essential for fuel cells since sulphur containing compounds and CO, will passivate the catalysts of the fuel cell.

|

Colour code |

Definition |

Advantages |

Disadvantages |

|---|---|---|---|

|

|

Naturally occurring H2 through fracking and underground deposits. |

Clean H2, although it might require purification form fuel cells |

Rare, early stages of development and still at the demonstration level. |

|

|

From water electrolysis and renewable energy sources, solar, wind, and biomass processes. |

1. Recycling |

1. High costs, more than blue H2. |

|

|

From Steam Methane Reforming (SMR) of fossil fuels. |

The most common form of production. |

1. Emits CO2 2. Emits other GHG 3. Continued use of fossil fuels. |

|

|

From natural gas through the SMR capture and bury GHGs.

|

1. Capture and remove GHGs using carbon capture and storage (CCS) technology. 2. Low-carbon hydrogen. |

1. Emits CO2. Does not meet international GHG emission reduction targets. |

|

|

Steam methanation of renewable natural gas with CCS. |

1. Carbon capture and storage (CCS). |

2. Emits large amount of CO2. |

|

|

From the pyrolysis of methane (thermal splitting). |

1. Produce H2 & solid carbon. 2. Valued as low-emission H2 in the future, depending on several factors. Efficiency 50%. |

1. Generate a small number of GHGs 2. Consumes 1/7 of the energy necessary to produce H2 electrolysis. |

|

|

Produced by coal gasification. Most hydrogen comes from this method. |

1. Liquefied H2 for low emission. Efficiency: 65%-75% |

1. Emits large amounts of CO2, CO & other GHGs. (Opposite to green H2). |

|

|

Chemo-thermal electrolysis from nuclear power plants. |

1. Low carbon emissions. |

2. High temperatures from a nuclear reactor. |

|

|

Use of nuclear energy to power water electrolysis. |

1. The steam generated from the nuclear reactors used for other H2 productions for more efficient electrolysis. |

2. High temperatures from nuclear reactors. 3. Generate a small amount of GHGs. |

|

|

From the energy grid via water electrolysis. |

1. Produced through electrolysis and can be combined with solar power. |

2. Carbon emissions vary depending on the sources used to power the grid. |

|

|

The thermal energy from nuclear power for high-temperature catalytic water splitting. Small nuclear power plants are implemented to augment wind, solar, and battery technology in the power sector. |

1. No CO2 emissions. |

1. Uses high temperature. 2. Generate a small amount of GHGs. |

|

|

From waste plastics through gasification or pyrolysis with CCS. |

1. Low raw material costs 2. Requires less energy. |

1. Early stages or research & development, more investigation is required. |

Table 1. Classification of hydrogen generation by colour code. Adapted/modified with permission from reference [6].

Hydrogen from renewable sources

There are several ways to generate hydrogen from renewable sources with some at the early stages of development or niche applications and others well developed but expensive for hydrogen mass production. Figure 2 shows two main classifications for renewable hydrogen production: biomass and water-splitting processes, each one divides in several technologies. Selecting the right methodology might depend on the application or the environmental limitations.

Water splitting

This technology generates the purest hydrogen gas but requires high-energy input and therefore it might be expensive. Three different methods include:

1. Electrolysis. - if the electricity to break the water into hydrogen and oxygen comes from nuclear energy or renewable energy sources such as wind, solar or biomass, the hydrogen produced will be CO2 free. Pure hydrogen is mainly used in the pharmaceutical or the electronic industries, but the increase of renewable sources opens the possibility to use it for fuel cells and transport or mobile applications. The cathode and anode electrodes produce hydrogen and oxygen, respectively. Alkaline electrolysis is the most common process because the oxygen evolution uses lower energy (low overportential) in alkaline environments than in acidic media, with a typical conversion efficiency or 60-70 %. There is also the proton exchange membrane (PEM) and anion exchange membrane (AEM) electrolysers that are slightly more efficient within 70-80% conversion efficiency [10].

2. Thermolysis. – Use of heat, which requires special materials able to resist temperatures of around 2500 OC to break the water molecules [11]. Since this is not a sustainable process, as there is not an abundance of materials able to resist such high temperatures continuously, the option is to use oxidation/reduction cycles of chemicals compounds. For example copper-chlorine (Cu–Cl), iodine-sulphur (I–S), cerium-chlorine (Ce–Cl), magnesium-chlorine (Mg–Cl), magnesium-iodine (Mg–I), vanadium-chlorine (V–Cl), iron-chlorine (Fe–Cl), hybrid chlorine, hybrid sulphur (HyS), and copper-sulphate (Cu–SO4) which can cycle at lower temperatures to around 800 OC and Cu–Cl cycle, at 540 OC. These processes have overall efficiencies between 30-50% [12].

3. Photolysis. – this is a promising cost effective and efficient technique that use a photoelectrochemical cell to take advantage of photo anodes using the sun light to split water. The cell uses a semiconductor material as photoelectrode to generate voltage from the absorption of solar energy. This is an environmentally friendly process for H2 generation but needs a catalyst able to reduce the activation energy of water splitting, Some typical catalyst are based on ruthenium, palladium, iridium, platinum and their alloys but the challenge is to find a lower cost catalyst with the right bandgap and able to maximise hydrogen binding energies. In general, photolysis has low conversion efficiency (1-5%) but coupled with a photoelectrochemical cell can reach 20% [13].

Biomass

Biomass is a low carbon dioxide emissions process that involves decomposition of organic materials. Hydrogen production can take in two different processes: thermochemical and biological:

1. Thermochemical. – involves the use of high temperatures to separate hydrogen from materials such as cellulose, lignin or wood sawdust among others [14].

a. Gasification. - converts the chemical energy into a combustible gas in two phases. Biomass in presence of air at temperatures between 500-1400 OC produce carbon monoxide and hydrogen (syngas mixture).

b. Pyrolysis. – biomass in an oxygen free environment at 500–900 OC and degasified at 0.1–0.5 MPa pressure produce hydrogen gas and other products such as methane or carbon monoxide from secondary reactions.

c. Combustion. - converts the chemical energy of carbon in biomass into heat and light in one step.

d. Liquefaction. – has potential for biofuels production, and the hydrothermal liquefaction in aqueous media can produce hydrogen and methane via gasification.

2. Biological. - biodegradable materials, agricultural waste and sewage sludge can produce hydrogen as an alternative environmentally friendly, less energy intensive process operating at ambient pressure and temperature [15].

a. Biophotolysis. – using cyanobacteria and green microalgae and sunlight, this clean and sustainable energy process use water as the main electron donor and can yield H2:O2 ratio at 2:1, with no CO2.

b. Dark fermentation. - anaerobic microalgae at 25 - 80 OC temperature follows several biochemical paths such as enzymatic hydrolysis of organic molecules to generate hydrogen. The yield is lower than photolysis but does not rely on sunlight energy.

c. Photo fermentation. - consist of the metabolic conversion of different organic molecules to bio hydrogen in presence of N2 and light. Due to its early stages of development, it cannot compete commercially with other hydrogen production processes.

Conclusion

Hydrogen as energy carrier has the potential to replace fossil fuels. However, as shown above is not easy to produce it without the use of fossil fuels either to provide the energy for water splitting or to provide the raw materials used in the steam reformation reactions. Using renewable energy sources is ideal for hydrogen generation but relies on the availability of effective wind turbines and photovoltaics to generate electricity. The cost of this development is high and although challenging there have been substantial developments in this area. Other challenges include the development of the infrastructure to transport and distributing hydrogen safely and in sufficient quantities to satisfy the current energy requirements. There are significant advances in the development of photoanodes for water splitting and great advances in photovoltaics cells and wind power able to provide energy to generate green hydrogen. However, despite the benefits, it is important to recognise that hydrogen is just another energy carrier and suffers the same challenges of other energy carriers in terms of conversion efficiency to mechanical work, transportation, and safety.

Carlos Ponce De Leon Albarran

Professor of Electrochemical Engineering

Carlos Ponce de León is Professor in Electrochemical Engineering at the University of Southampton. His main areas of expertise include electrochemical energy conversion and water treatment technology, recovery of precious metals and fuel cell testing. Carlos is Principal Investigator of projects funded by the European Commission, and has organised conferences in electrochemistry, electrochemical engineering. He has authored over 200 peer-reviewed publications with an h-index of 51, with over 10,500 citations.

References

- https://www.nasa.gov/?search=greenhouse+emission

- Orbiting Carbon Observatory-2: Science (nasa.gov)

- https://www.gosat.nies.go.jp/en/recent-global-co2.html

- Markus Reichstein, Michael Bahn, Philippe Ciais, Dorothea Frank, Miguel D. Mahecha, Sonia I. Seneviratne, Jakob Zscheischler, Christian Beer, Nina Buchmann, David C. Frank, Dario Papale, Anja Rammig, Pete Smith, Kirsten Thonicke, Marijn van der Velde, Sara Vicca, Ariane Walz & Martin Wattenbach. Climate extremes and the carbon cycle. Nature volume 500, 287–295 (2013). https://doi.org/10.1038/nature12350

- https://www.chemistryworld.com/features/the-hunt-for-natural-hydrogen-reserves/4017747.article

- Bidattul Syirat Zainal, Pin Jern Ker, Hassan Mohamed, Hwai Chyuan Ong, I.M.R. Fattah, S.M. Ashrafur Rahman, Long D. Nghiem, T M Indra Mahlia. Recent advancement and assessment of green hydrogen production technologies. Renewable and Sustainable Energy Reviews Volume 189, Part A, January 2024, 113941. https://doi.org/10.1016/j.rser.2023.113941

- Holmen A. Direct conversion of methane to fuels and chemicals. Catalyst Today. 2009; 142:2–8. https://doi.org/10.1016/j.cattod.2009.01.004.

- Joensen F, Rostrup-Nielsen JR. Conversion of hydrocarbons and alcohols for fuel cells. J Power Sources 2002; 105: 195–201. https://doi.org/10.1016/S0378-7753(01)00939-9

- Lavoie JM. Review on dry reforming of methane, a potentially more environmentally-friendly approach to the increasing natural gas exploitation. Front Chem 2014;2. https://doi.org/10.3389/fchem.2014.00081

- D. Pletcher, F.C. Walsh. Industrial Electrochemistry. Chapman and Hall, 2nd edition 1990, pages 256-268.

- Steinfeld A. Solar thermochemical production of hydrogen - a review. Sol Energy 2005; 78: 603–15. https://doi.org/10.1016/j.solener.2003.12.012.

- Deng Y, Dewil R, Appels L, Li S, Baeyens J, Degr`eve J, et al. Thermo-chemical water splitting: Selection of priority reversible redox reactions by multi-attribute decision making. Renew Energy 2021; 170: 800–10. https://doi.org/10.1016/j.renene.2021.02.009.

- Aslam Hossain, T.C. Bhagya, E.A. Mukhanova, A.V. Soldatov, A.M.A. Henaish, Yuanbing Mao, S.M.A. Shibli. Engineering strontium titanate-based photocatalysts for green hydrogen generation: Recent advances and achievements. Applied Catalysis B: Environmental 342 (2024) 123383. https://doi.org/10.1016/j.apcatb.2023.123383.

- Binlin Dou, Hua Zhang, Yongchen Song, Longfei Zhao, Bo Jiang, Mingxing He, Chenjie Ruan, Haisheng Chen and Yujie Xu. Hydrogen production from the thermochemical conversion of biomass: issues and challenges. Sustainable Energy Fuels, 2019, 3, 314-342. https://doi.org/10.1039/C8SE00535D

- Ravindra Kumar, Anil Kumar, Amit Pal. An overview of conventional and non-conventional hydrogen production methods. Materials Today: Proceedings. Volume 46, Part 11, 2021, Pages 5353-5359. https://doi.org/10.1016/j.matpr.2020.08.793